0512-53943929

0512-53943929

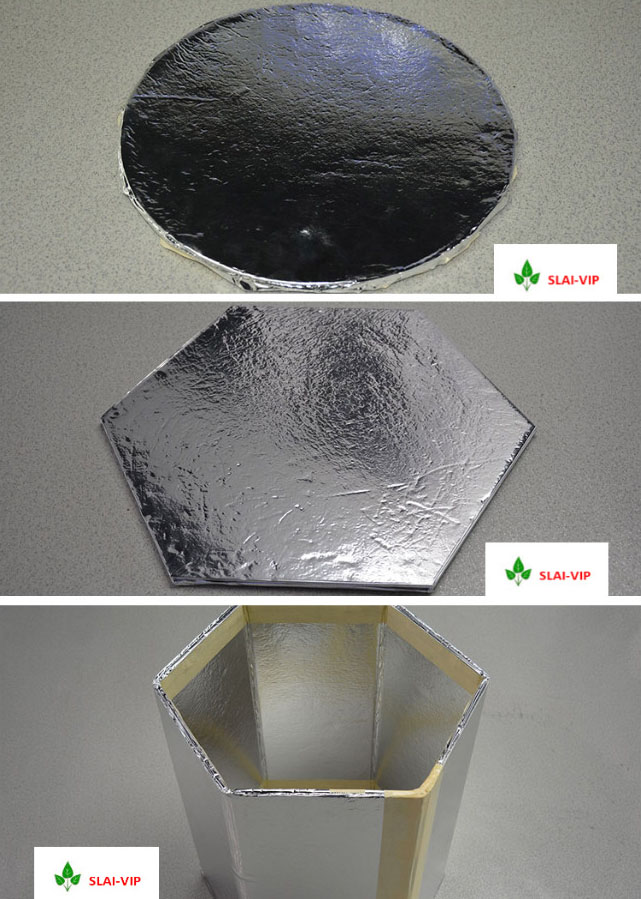

Application: cold chain transportation, refrigerator, freezer, etc

克利夫兰®C is composed of ultrafine inorganic fibers and vacuum aluminum foil packaging composite membrane, it can effectively prevent air convection caused by heat transfer, the obvious advantages over traditional heat preservation material coefficient of thermal conductivity is 0.002-0.010 w/m·k, and does not contain any OD material, has the characteristics of environmental protection and high efficiency and energy saving, is currently the world's most advanced and efficient heat preservation material.

Order hotline:0512-53943929

Product introduction:

克利夫兰® C vacuum insulation panel (hereinafter referred to as :克利夫兰® C), is made up of super fine glass fiber and vacuum aluminum foil packaging composite membrane material, it can effectively prevent air convection caused by heat transfer, thus can greatly reduce the thermal conductivity, thermal conductivity between 0.002 to 0.010 w/m k, and does not contain any OD material, has the characteristics of environmental protection and high efficiency and energy saving, is currently the world's advanced efficient thermal insulation material.